An Open Letter from Christian M. Joest

President Emeritus , Imperial Machine & Tool Co.

My grandfather, Michael Joest, was a hard-working fellow. He came to America from Germany as a young man who, like so many others, wanted to make a better life for himself and his new wife. After many years of working as a toolmaker for Western Electric he seized on the opportunities WWII provided and set off to make his mark on his own. He founded Imperial Machine & Tool Co. with a strong belief in “doing what’s right”.

Michael and Elizabeth Joest

Over the years Michael proved himself an astute businessman and through perspiration and persistence the company continued to grow and prosper. I remember my grandfather well and often think of him as time unfolds. He would have been fascinated by CNC machining let alone current Additive Manufacturing techniques.

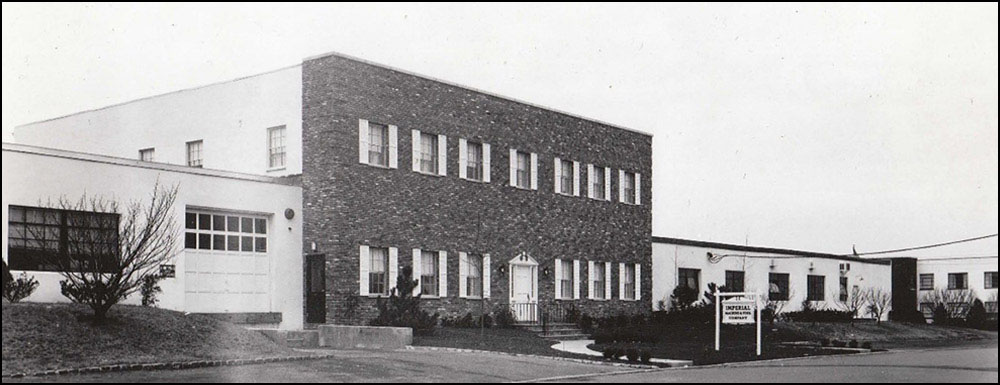

Imperial’s first expansion, a state of the art facility built in Cedar Grove NJ. Photo: 1965.

My dad, George Joest Sr., took over the company in the early 1960s. It was time for Imperial to expand beyond military work and as a trained mechanical engineer and lover of innovative technology, he began exploring the nascent computer industry.

Within a few years Imperial had grown to be a major supplier of semiconductor equipment and components to the budding IBM. This early work with IBM and others allowed Imperial to develop unparalleled expertise working with refractory metals like Tantalum, Titanium and Molybdenum.

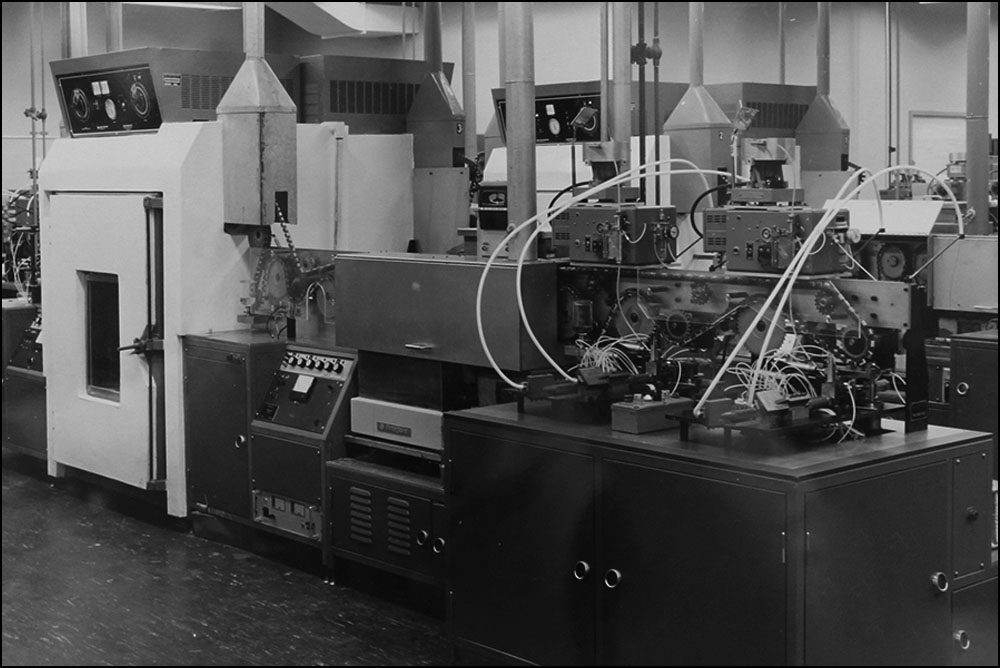

One of Imperial's early "Die Capping" machines, used to make integrated circuits for IBM. Circa 1960s.

My dad ran Imperial for over 20 years, becoming an early adopter of computer controlled machining and setting the stage for the wave of innovation and change that was soon to take place.

In 1988 my brother George Jr. and I took the reins and over the next 20 years we expanded Imperial's capabilities even further. We truly focused on tackling the most challenging jobs around and married that with the mantra of “never let our customers down”. This unflinching dedication to Quality, Innovation and Service enabled the company to experience tremendous growth in new markets and technologies. In 1996 we built a 30,000 sq-ft state of the art facility Columbia, NJ. This completed our transition from manual machining to a full CNC facility. Today Imperial runs 40 top of the line multi-axis precision CNC machining centers.

New CNC equipment being delivered. It was a tight squeeze but we got it in place!

In 2008, with his kids grown and a yearning for the outdoors, George retired from Imperial and he and his wife Laureen moved to their ranch in Wyoming. He now co-owns a gunsmith shop in Cody and they do really cool work, particularly on old Winchesters.

Our most recent milestone has been the addition of Metal Additive Manufacturing through Powder Bed Fusion (3D Metal Printing) to our extensive suite of services. While we have long utilized polymer additive techniques, with the acquisition of our first SLM 280 HL in 2013 we began our foray into making the impossible possible. We felt this technology was particularly suited for Imperial. As we began assessing the technology we immediately came to realize that a precision machine shop like Imperial is the required fit for Additive since almost all 3D printed metal structures require machining operations after they are “printed”.

We regularly work in areas that benefit from an Additive approach. By aligning ourselves with our customers and working closely together to bring new designs and innovations to market we have enjoyed great success. Enough success in fact to buy our second SLM tool in 2015. Imperial has the corporate temperament and financial strength to be able to effectively harness a new technology like Additive and we continue to push the bounds for our customers.

These days, my son Christian helps us navigate the world of Advanced Manufacturing and heads up our Business Development activities. He grabbed the Additive Manufacturing bull by the horns and enabled Imperial to establish our leading position in Additive. Our investment in this powerful technology is already paying off, redefining what is possible in the world of manufacturing.

We're proud to be early adopters, and are confident that metal 3D printing will be a key manufacturing technology for future generations.

Two of our SLM 280 HL metal 3D printers in our additive manufacturing laboratory.

Imperial is more than just a company to me; it's an integral part of my family and our history. It's my grandfather's and fathers living legacy and our family is fortunate to have something we cherish so much. Not only is it how I support my family but also the dozens of families of our workers. We care very much about a successful outcome here at Imperial. Whether that be our customers realizing their long dreamed of design or an employee’s long cherished hope of home ownership and a college education for their kids. We still believe in “doing the right thing” just like my grandfather. Now in our 4th generation the principles of “doing what’s right” are still what guide the company and hold the key to our many decades of success.

We strive to provide our customers the best possible product and the highest levels of customer service in the industry. We marry that with a willingness to embrace challenges. We offer our employees a career, not just a job, and provide continuing education and training for a lifetime. While a lot has changed since 1943 the basics haven’t. Hard work pays off, integrity is more important than money, and the dedication to “doing what’s right” leads to success.

If you're looking for an advanced manufacturing partner, one that believes a positive outcome is one where all parties benefit, I sincerely hope you consider getting to know Imperial. I can assure you of our hard work, our integrity and our dedication to our time honored principles of Quality, Innovation and Service. If you think we would work well together, please reach out and we can discuss your manufacturing needs.

Sincerely,

Christian M. Joest (Chris)

President Emeritus

Imperial Machine & Tool Co.