An Intro to 3D Printed Support Structure

We're often asked,

"What is 3D Printed support structure?"

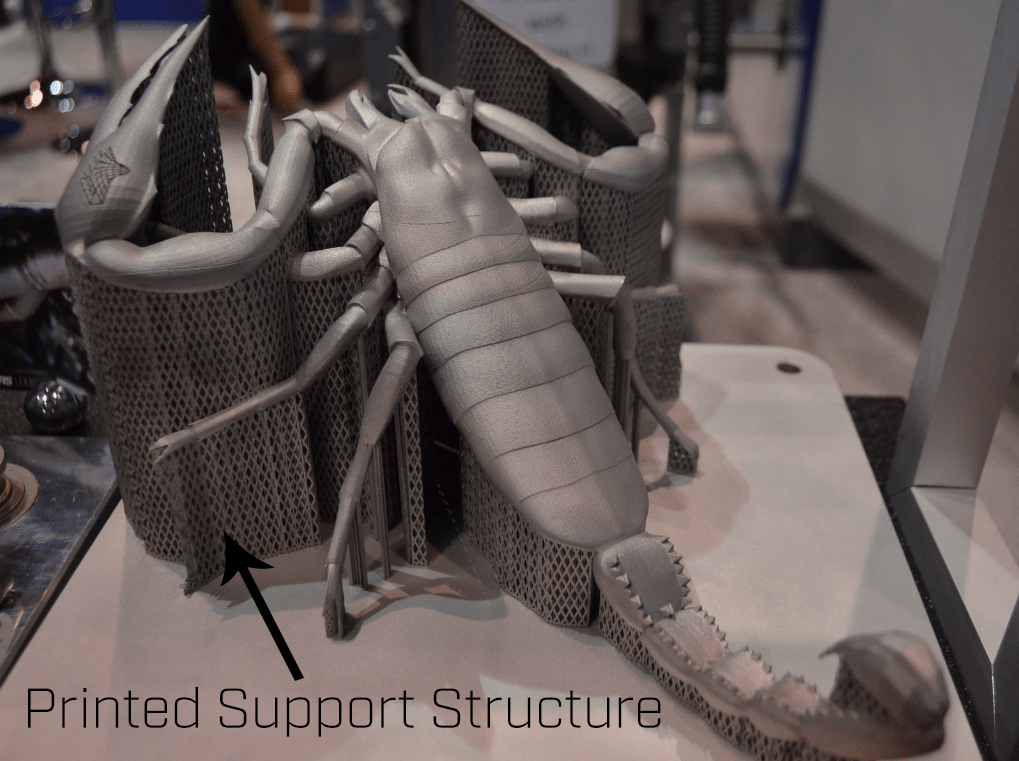

"3D Printed Support Structure" is sacrificial support material used when printing over-hanging features. It's primary purpose is to support design elements that would otherwise droop or sag.

Much like construction scaffolding, support structure is used during the build process, and removed later on.

This Scorpion build is a nice visual example of printed support structure. Without support, this build would have failed. After the build is completed the support structure is removed, leaving the original design. "Thank you" to the folks at 3D Printing Industry for sharing this picture with us.

Why do we use printed support?

Support structure prevents features from caving in or drooping.

The additive manufacturing process builds parts layer-by-layer (you can see a video of the process here), and it's impossible to "Print" a layer on top of nothing. This is where 3D printed support structure comes in.

A simple example that illustrates this concept is a Mushroom vs. a Martini glass.

Let's consider the mushroom first. The base/stem of the mushroom will print fine, but when the 3D printer reaches the "cap",the build will fail. The cap will cave & droop since there's nothing underneath it. We must use support structure under the cap of the mushroom to yield a successful print.

The Martini glass, on the other hand, will print well with no support at all. Each layer gradually steps out, making the structure "self supporting". This concept of layers gradually stepping out is the key to understanding the next important topic.

The 45° Rule & Self-Supporting Structures

We tell customers to keep 45° in mind when designing components to be 3D printed. Overhang features that are above 45° will print well without support.

Overhang features less than 45° usually require support, depending on material, parameters and geometry.

When proper design for AM principles are employed, it's possible to create structures that don't require any support at all. These structures print faster, use less material and require substantially less post processing, which translate directly into cost savings.

This Impeller example employs printed support structure on overhangs less than 45°, then continues "un-supported" for the overhangs greater than 45°.

Self Supporting Structure examples:

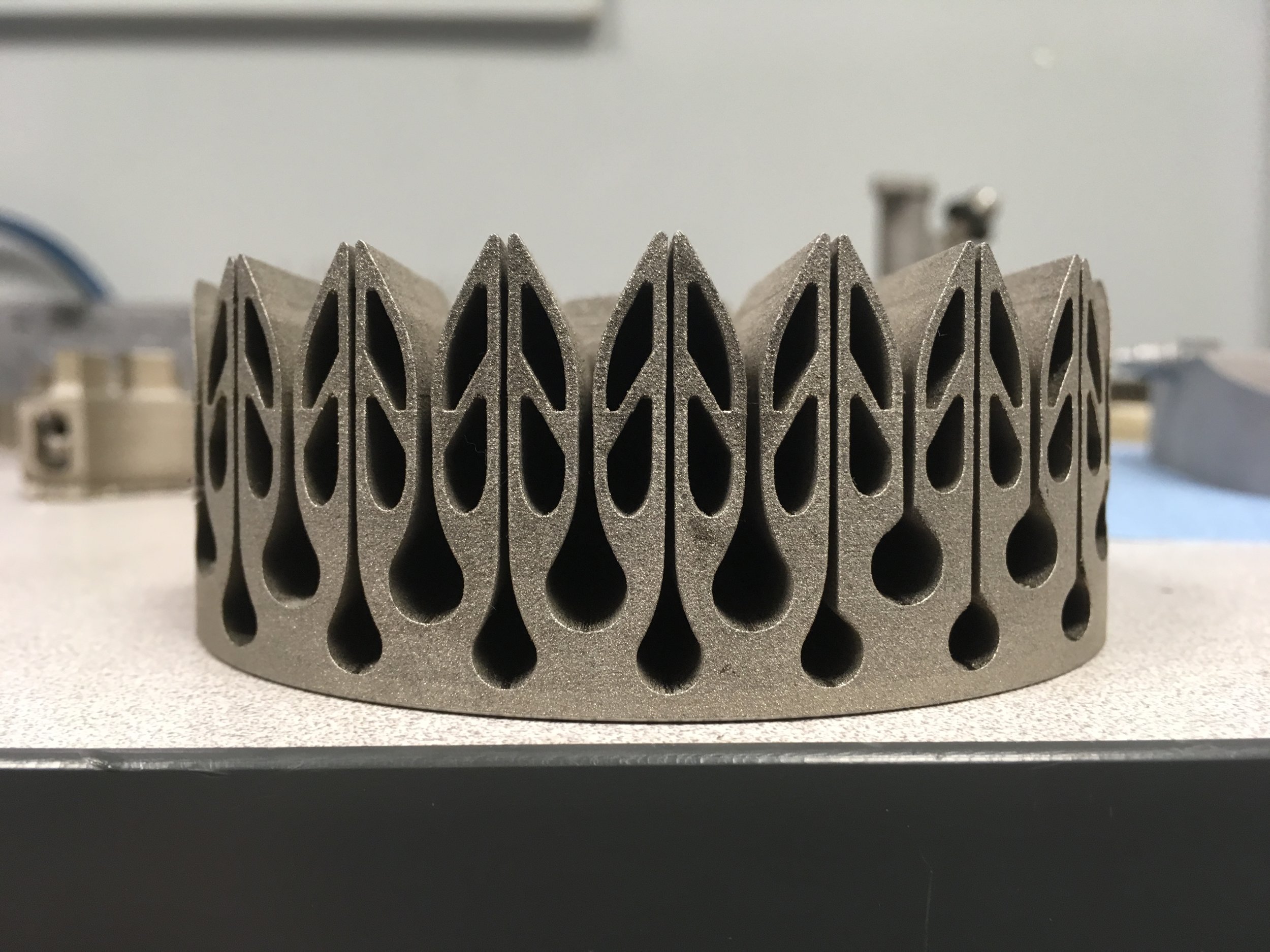

Thermal Break - Entirely Self Supporting Structure. Everything abides by the 45° Rule.

Conformal Cooling Passages - Entirely Self supporting, and vastly improved cooling performance over drilled cooling channels

Choosing Build Orientation

Occasionally, real-world constraints prevent a CAD design from being modified to enable "self support". In some instances, we can manipulate build orientation to minimize support, like in this heat exchanger example.

This Heat Exchanger would not print successfully if the design were "sitting flat" on the build plate.

By tilting the entire part by 45°, all of the features are now self supporting. This particular component was selected for the cover of Metal 3D Printing Magazine.

A Metal 3D Printed Heat Exchanger, manufactured at Imperial's Columbia, NJ headquarters. This project was a collaboration with Penn State's CIMP-3D facility.